advantages of producing 3d drawings

With manufacturers across industries racing to increase productivity, every new applied science and process could mean another step ahead of the contest. As a upshot of this button for more productive methods, many companies have made, or are making, the switch from 2D to 3D modeling —for a number of fantabulous reasons.

Where 2D modeling limits and slows teams' access to product pattern information, 3D solid modeling expands that access and agreement. This improved catamenia of information eliminates structural inefficiencies, human errors, and other factors that weigh down the design bicycle. Ultimately, 3D scanning applied science increases the efficiency and speed of the design and manufacturing processes, resulting in price savings, quicker fourth dimension-to-marketplace, and increased opportunities for production innovation.

Whether yous're a manufacturing engineer nonetheless relying on 2D drawings or a new product designer looking for faster, more efficient ways to brand their blueprint a reality, it may exist fourth dimension to make the switch to 3D modeling. Let's dive into the advantages of this method over 2D modeling and find out how highly accurate 3D scanning engineering science tin can speed upwards workflow even further.

half-dozen Advantages of 3D Modeling

1. Streamlined Product Design Cycles

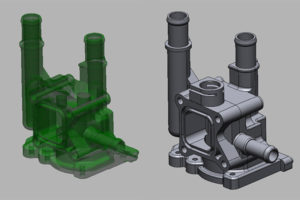

Browse Data and CAD

3D CAD software allows designers to explore a greater number of possibilities during the design process and make revisions quickly and efficiently—as opposed to painstakingly updating a 2D design. Recollect of this as a more than direct (and quick) road to the final product.

After all, time really does hateful money when it comes to product blueprint and manufacturing. That'south 1 of the about pregnant reasons that so many companies are turning their attention to 3D modeling. When compared to 2d modeling, 3D modeling is significantly faster. This timesaver simply tin can't be ignored, especially when it tin can permit you to put your product into production alee of your contest.

2. An Attainable Design Process

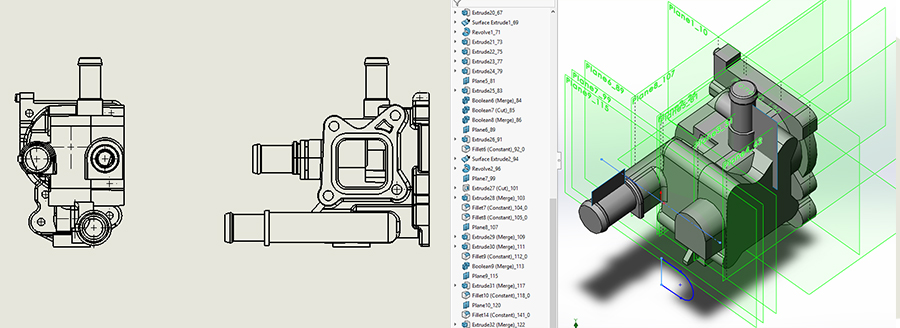

Changes made in the name of speed don't have to mean a corresponding drop in quality or a complication of the design and manufacturing processes. Automating your design process with the assist of 3D modeling software can really increment your productivity while also providing increased access to customers and internal personnel that might otherwise not take clear visibility into your work. Yous'll be able to chop-chop create both 2D and 3D renderings of your models, providing the visualization you lot need when and where your team needs it.

2d Drawing from CAD and CAD Model

3. Improved Communication Across Internal and External Teams

Ultimately, that increased accessibility leads to better communication throughout your company. Going from a 2d prototype to a 3D model besides allows for quicker and more productive internal pattern reviews. 3D modeling tin can as well foster more than effective advice with suppliers, customers, and internal teams, further cutting down on time-to-market.

Both clients and internal personnel will be able to visualize both components and the final product design more hands with the help of a functioning 3D model. The addition of blitheness creates an interactive model that provides an splendid idea of how the product volition function in real life. 2d modeling can't provide the same level of like shooting fish in a barrel visualization and quick comprehension.

As an added bonus, 3D solid modeling can be used to create animations and renderings for promotional content. The same goes for if y'all're working off of an existing prototype— 3D scanning tin can exist used to fabricate quick 3D CAD models for marketing and sales purposes.

4. Catch Pattern and Quality Bug Earlier They Cost You

Far too many resources are wasted on catching faulty designs and quality issues after production has already started. Why non beginning asking and answering circuitous engineering questions earlier in the process? 3D modeling allows your company to conserve those valuable resources by enabling you to catch errors before a blueprint is finalized. As an example, 3D modeling allows you to take hold of interference issues in an assembly at a indicate when changes to the design are less costly.

STL from Scan Data, CAD Model, Color Fault Map

Virtual 3D prototypes too reduce the demand for, and price of, creating concrete prototypes. Validating your designs digitally will reduce costs stemming from both blueprint and quality problems while maintaining the integrity of your blueprint process.

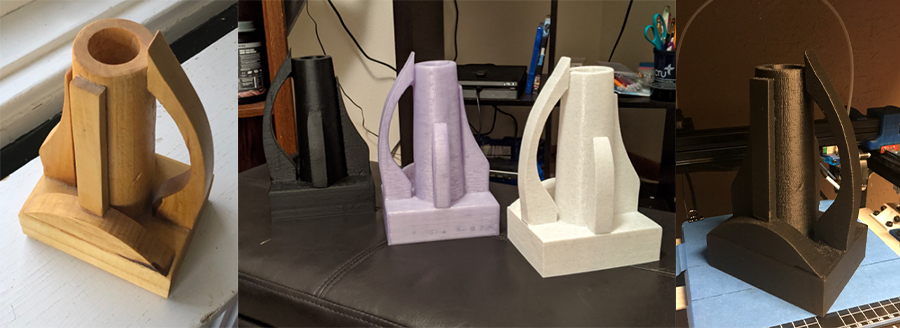

5. Physical Prototyping Fabricated Simple

If you take a continued need for physical prototypes, we suggest notwithstanding another applied science that is chop-chop growing in popularity: 3D printing . 3D CAD models can hands be converted to STL files for 3D printing prototypes. This form of rapid prototyping allows multiple teams to participate in the process, while leaving designers and engineers able to easily incorporate and test design changes at whatever stage of the process. With the combined might of 3D modeling and 3D printing, you'll be able to test and validate your prototypes earlier beginning production.

Original wood piece and 3D printed prototypes

vi. More Effective Data Direction

Efficient data management is e'er a business for manufacturers and designers, specially when working with numerous revisions and evolutions of products. It's quite possible that some designers and engineers who adopt 2D modeling are simply more comfortable manually organizing their drafts. Just making the switch from 2d to 3D modeling can drastically increase efficiency.

3D modeling allows you to easily keep track of your design data. Instead of having to update a Bill of Materials (BOM) with every single design modify, for case, 3D modeling software can automatically update the BOM as components are added or removed from an associates. This helps to consolidate drafting practices and keep your entire team on the same page. And, as we've mentioned, 3D solid modeling simplifies data substitution with other departments, keeping the product pattern cycle straightforward and avoiding whatever potential redundancies or repeated work.

Pace Into the Future With 3D Modeling and Laser Scanning

At that place's no better time to make the move from 2nd to 3D modeling than today. And if yous're looking to speed up the design and manufacturing procedure even further, y'all may want to consider upgrading your electric current setup and introducing 3D scanning into your workflow.

Light amplification by stimulated emission of radiation Design, a CyberOptics Corporation brand, has been sharing this powerful technology with the world for over 30 years. Our 3D scanning services team can capture 3D measurement data for objects big and small, and even vehicles and buildings, and and then create the highly accurate 3D CAD models in the native file formats yous require. We also offer point deject modeling-only services to help you have your own 3D scan information to CAD format. Attain out today for more information—we look forward to working with you!

Source: https://www.laserdesign.com/benefits-of-3d-modeling-and-why-2d-is-limited/

Kommentar veröffentlichen for "advantages of producing 3d drawings"